Nescafe Dolce Gusto Capsules Filling Sealing Machine is the Newest design Machine use for Dolce Gusto Filling and Sealing. In this machine, we can realize double sealing function which make it total same with the original dolce gusto capsules. This Dolce Gusto Capsules filling sealing machine include many special design include special design high speed nespresso cups feeding, servo motor control filling and special discharge device.

Table of Contents

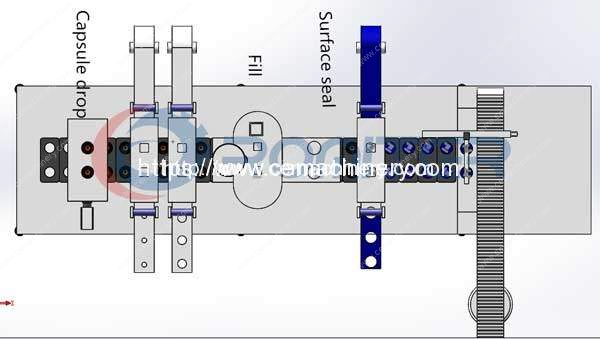

Working Process of Dolce Gusto Capsules Filling Sealing Machine

- empty dolce gusto capsules feeding system.

- Automatic drop empty capsules to machine ( the bottom of capsules samples was already sealed )

- Automatic detect whether dolce gusto capsule well loated on the machine by sensor.

- filling Nitrogen into capsule.

- Servo motor to fill coffee while vibrating, weight around 5-20g ( can be adjust), also second time filling Nitrogen into capsule.

- Filling dolce gusto pods flavours.

- Sealing paper filter from roll on inner body of capsules.

- Auto cutting paper from roll and seal on the top of capsule

- Auto Seal on the top of capsules second times.

- Automatic exit to transport the finished dolce gusto to conveyor

We provide customized Nescafe Dolce Gusto Capsules Filling Sealing Machine for customer, if there is any need, feel free to contact us

System Structure Drawing for Dolce Gusto Capsules Filling Sealing Machine

Specification of High Speed HRML Series Coffee Capsules Filling Sealing Machine

| Model | HRML-1 | HRML-2 | HRML-4 | HRML-6 |

| Speed | 1800cups/hour (30pcs/min) |

4800cups/hour (80-100pcs/min) |

9600cups/hour (160-200pcs/min) |

14400cups/hour (240-300pcs/min) |

| Working Station | single lanes | two lanes | four lanes | six lanes |

| Filling Range | 0-20grams | 0-20grams | 0-20grams | 0-20grams |

| Filling Accuracy | ±0.05~0.15 | ±0.05~0.15 | ±0.05~0.15 | ±0.05~0.15 |

| Hopper Size | 2.5L-110L | 2.5L-110L | 2.5L-110L | 2.5L-110L |

| Cotrol System | PLC(OMRON, SCHNEIDER, ROCKWELL) | PLC(OMRON, SCHNEIDER, ROCKWELL) | PLC(OMRON, SCHNEIDER, ROCKWELL) | PLC(OMRON, SCHNEIDER, ROCKWELL) |

| Touch Screen | 7 Inch | 10 Inch | 10 Inch | 10 Inch |

| Voltage | Customized available | Customized available | Customized available | Customized available |

| Compressed Air | ≥0.8Mpa/0.1m² | ≥0.8Mpa/0.1m² | ≥0.8Mpa/0.1m² | ≥0.8Mpa/0.1m² |

| Working Temperature | 5-35°C | 5-35°C | 5-35°C | 5-35°C |

| Relative Humidity | ≤85% | ≤85% | ≤85% | ≤85% |

| Dimension(mm) | 2490*1250*2100 | 4880*1000*2100 | 3720*1200*2150 1750*1200*2150 |

3720*1400*2150 1750*1400*2150 |

| Weight | 600kg | 960kg | 1150kg | 1350 |

| Package Weight | 650kg | 1000kg | 1250kg | 1450 |

Working Vide of HRML-1 Dolce Gusto Capsules Filling Sealing Machine

Company Profile

Romiter Machinery Co., Ltd. is a market-leading designer and manufacturer of coffee capsule packing machines. Romiter Machinery wins a wide reputation for high-quality machines with high efficiency, excellent reliability, easy maintenance, long lifespan and an excellent technical support team.

Now, Our factory can provide Rotary Type Nespresso Capsules Filling Sealing Machine, Linear Type Nespresso Capsules Filling Sealing Machine, Nespresso Capsules Sealing Machine, Nespresso Capsules Box Packing Machine, Semi-Automatic Nespresso Capsules Filling Sealing Machine, Automatic Nespresso Coffee Capsules Bag Packing Machine, Automatic Empty Nespresso Cup Ordering Feeding Machine, Round Nespresso Coffee Pod Filling Sealing Machine, Empty Aluminum Nespresso Cups, Empty Biodegradable Nespresso Cups, Kcups Nespresso Coffee Capsules Filling Sealing Machine, Nescafe Dolce Gusto Coffee Capsules Packing Machine, Tea Capsules Filling Sealing Machine, Lavazza Blue Coffee Capsules Filling Sealing Machine, and Coffee Milk Pod Thermoforming Filling Sealing Machine

Romiter potato processing machine has passed with CE, ISO and SGS Certificates and has been widely sold all over the world.