Manual Book of Manual Coffee Capsules Sealing Machine

The unite described in this manual and the manual itself were designed and manufactured according to regulations with safeguard the operator and anyone in proximity of the unite.

This manual is an integral part of the unit and must be kept with the unit. The buyer is required to keep the manual in good condition and contacting the sater if damaged.

Attention:

Before moving ,using or interacting in any way with the unit it is mandatory to read the user’s manual. It is also mandatory that the buyer requires the operator to read and understand the manual.

Table of Contents

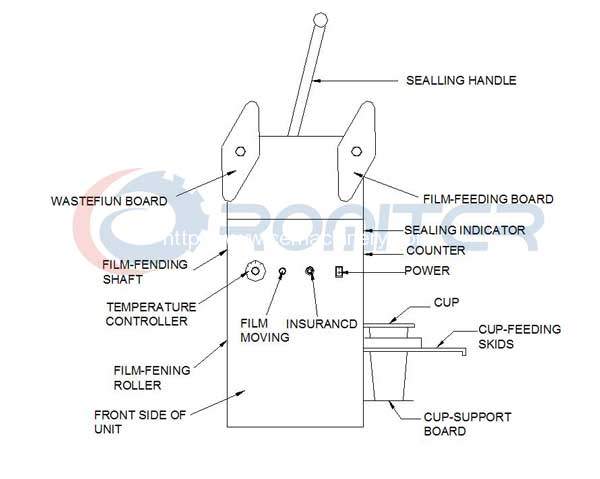

Ⅳ.INTRODUCTION OF USE

- temperature button

connected with power, turn temperature button to 180℃~190℃,it will take around 5-10 minutes to heating up. When heating work is finish, the green indicator lamp will become red, At this time, the unit is ready for sealing work.

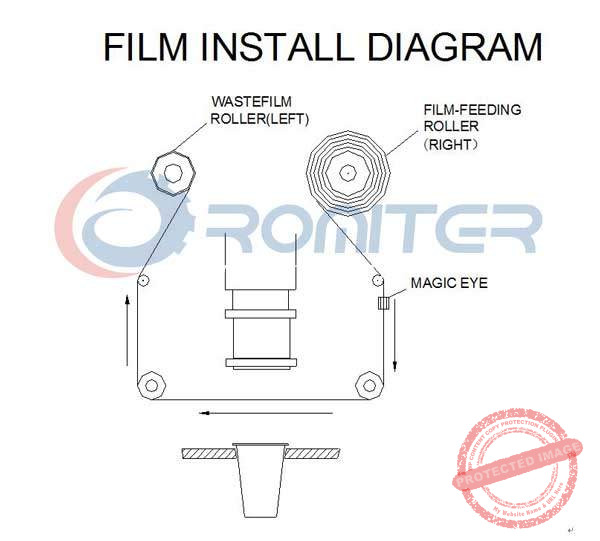

- film-moving button

whenever there is a new film roll is installed, press the film-moving button, the film will turn to the right place for sealing work, Don’t need touch this button,until the next new film roll is installed.

- cup-feeding skids

when the heating work is finished, the unit is ready for sealing work, put cup to skids, push the skids inside of unit, then press the sealing handle, release the handle when the indicator lamp flash.

Attention: the temperature should be adjusted according different thick of film, too high temperature will destroy the film and cup. And the residual film and cup will make work-table bumpy, then result sealing leakage.

- counter button

when unit finish the whole work, turn the counter to reset place.

- small cup mould

when seal small cup, put the small cup mould to cup feeding skids, then sealing work can start.

Ⅴ. MAINTENANCE

- before sealing work, make sure the opening of cup is clean.

- try to avoid high temperature, and long sealing time to destroy the film and cup, and the residual film of cup will make work-talbe bumpy.

- to make high sealing quality, check and clean the surface of sealing termly.

- Clean the cup-feeding skids termly.

- keep all chamfer and all bearing system of cup-feeding skids clean and the bearings should be fuelized termly.

- when unit breakdown, cut power supplier first.

Ⅵ. SPARE PARTS WITH UNIT

| NAME | QUANTITY |

| SMALL CUP MOULD | 1PC |

| CUP | 1PC |

| 5A FUSE | 2PCS |

| M6 ALLEN WRENCH | 1PC |

| CROSS SCREWDRIVER | 1C |

Company Profile

Romiter Group is a market leading designer and a manufacturer of coffee capsule filling sealing machinery, include coffee capsule packing machine, coffee capsules filling sealing machine, nespresso capsules filling sealing machine, k-cup filling sealing machine, lavazza blue capsules filling sealing machine, coffee pod filling sealing machine, coffee pod packing machine, coffee bean roasting machine.