Coffee capsule rotary filling and sealing machine can automatically finish the processes of falling empty K-cup, filling, sealing, capsules out from machine. It is mainly used in the products packing like: coffee powder, milk powder, rice, wheat powder and so on. Coffee capsule filling and sealing machine adopts brand PLC, advanced pneumatic control components, touch screen and 304#stainless steel frame. Automatic coffee sealing parts can seal with high strength, good sealing and low failure rate. In addition, it can be customized according to special requirements.

Romiter coffee capsule rotary filling and sealing machine is compatible for all coffee capsules product, we have successful experience design and manufacture for all kinds of coffee capsules: small capsules like 5 and 10 grams. Romiter Machinery has over four years of production experience in this machine and has exported more than 100 machines to Brazil, USA, France , Singapore, Australia, Canada, Spain, New Zealand, UK, India, etc.

Table of Contents

Feature of Coffee Capsule Rotary Filling and Sealing Machine

- Advanced design: Romiter Group coffee capsule rotary filling and sealing machine adopts the most popular advanced mechanical and electrical control system(dual control PLC), which is with compact structure, high automation control.

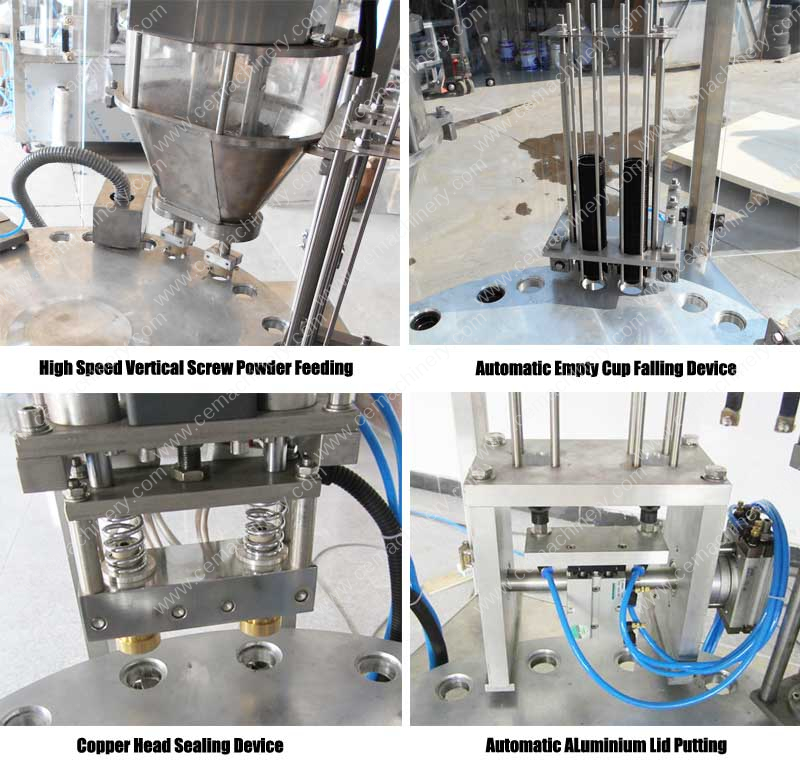

- Easy to operation: Automatic completion of the delivery cup, falling cup, filling, mechanical hand suck film, sealing, hand out the cups and other mechanical functions, stable performance, simple maintenance, and high production efficiency and 24-hour continuous work.

- High-quality material: components (eg, stainless steel, aluminum, copper and other corrosion-resistant) are in line with food hygiene law.

Working Process of Coffee Capsule Rotary Filling and Sealing Machine

- put cup

- automatically drop down cup

- uv sterilization

- nitrogen flushing

- filling

- put pre-cut

- twice sealing

- automatically out of cup

Working Process of Rotary Coffee Capsules Packing Machine

Specification of Rotary Type Coffee Capsules Filling Sealing Machine

| Model | RMY-1 | RMY-2 | RMY-3 |

| Filling heads | 1 | 2 | 3 |

| Capacity(Kcups/Nespresso pcs/hour) | 1400/1800 | 2800/3600 | 4200/5400 |

| Filling volume | 3-30g | ||

| Accurate | ≦±0.2g | ||

| Power | 2.5kw | 3kw | 3.5kw |

| Power source | AC 380v/50 Hz 3 phases | ||

| Air consumption | 0.7m3/min | ||

| Heating temperature | 0-400℃ | ||

| Weight | 600 kg | 650kg | 700kg |

| Dimension(mm) | 1660*1090*1700 | 1700*1190*1700 | 1800*1290*1700 |

Note: We can provide customized coffee capsule filling and sealing machine according to customer’s requirement.

Working Video of Rotary Kcups Capsules Filling Sealing Machine

Working Video of Rotary Nespresso Capsules Filling and Sealing Machine

Working Video of Old Coffee Capsule Rotary Filling and Sealing Machine

Company Profile

Romiter Group is a market leading designer and a manufacturer of coffee capsule filling sealing machinery, include coffee capsule packing machine, coffee capsules filling sealing machine, nespresso capsules filling sealing machine, k-cup filling sealing machine, lavazza blue capsules filling sealing machine, coffee pod filling sealing machine, coffee pod packing machine.